STRIVING FOR SUSTAINABILITY AND A GREENER PLANET

At the end of the 1970s, the automotive industry was booming, leading to a major waste problem with end-life-tyres, also commonly referred to as ELTs, scrap tyres or simply used tyres. As tyres only slowly degrade in landfill sites, an alternative disposal method was required. The idea of establishing a plant for the recycling of ELTs was born.

During the 1980s, this idea was further developed; and in 1990, the first Genan recycling plant for end-of-life tyres became a reality in Viborg, Denmark. The production capacity was 35,000 tonnes of mixed ELTs (i.e. tyres from passenger cars, vans, trucks, tractors and large earth-movers).

During the 1990s, the Danish factory was continually developed and improved; and in 2011, the production capacity of the Viborg plant was doubled to 70,000 tonnes.

In 2003, on the basis of the knowledge and experience gained from the Danish plant, Genan opened its second tyre recycling plant in Oranienburg, on the outskirts of Berlin, Germany. The production capacity was 65,000 tonnes of ELTs per annum.

Five years later, in 2008, a 70,000 tonne plant opened in Dorsten, Germany. When a third German plant with a similar capacity started operation in Kammlach, Bavaria, in 2010, the Genan recycling plant strategy for Germany was complete.

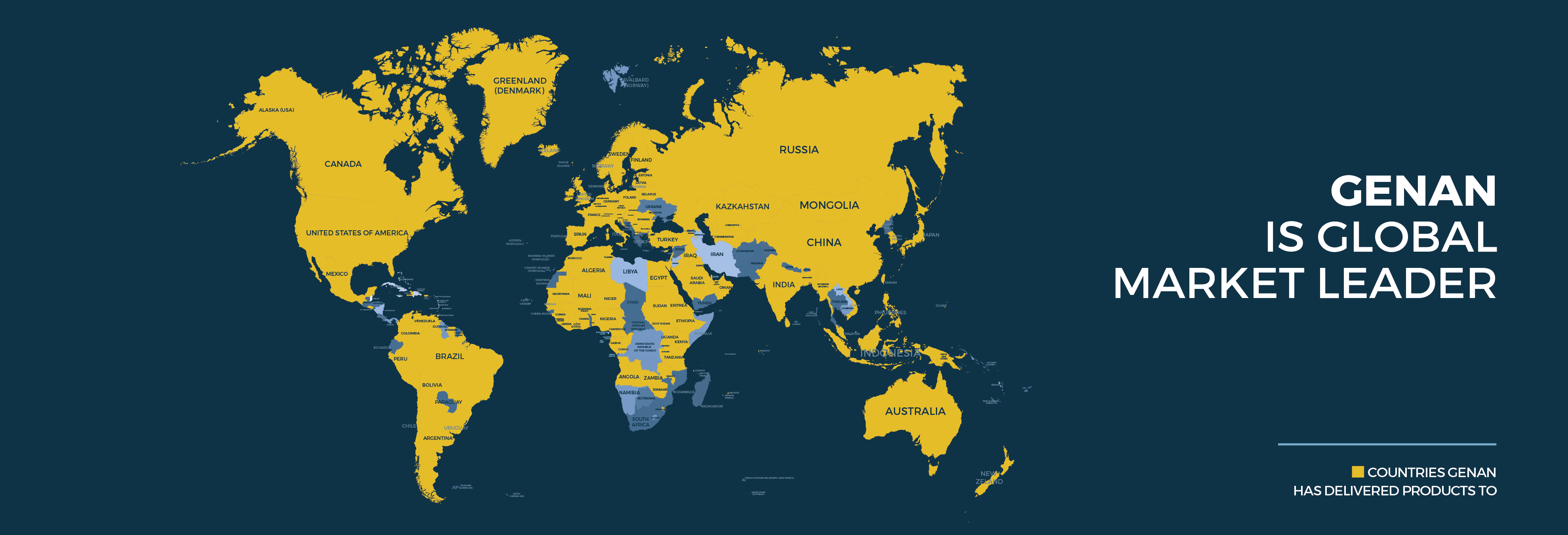

Aiming to globally further the recycling of end-of-life tyres in the environmentally and economically most beneficial way, Genan expanded operations with its first non-European plant in 2014, when the world’s largest tyre recycling plant was opened in Houston, Texas, USA, boasting an impressive 100,000 tonne annual production capacity.

Believing that true recycling requires processing at a level where the output substitutes virgin raw material, Genan is continually investing time and resources in improving and identifying new applications for its products.

An R&D project on cryogenic milling was initiated in 2011; and in 2015, production of micronised powder was started up in Viborg. Genan now supplies ultra-fine rubber powder of such high, consistent quality that it can even be used in the manufacture of new tyres. Genan thus pioneers by offering true cradle-to-cradle tyre recycling.

In 2017, Genan launched the product GENAN PELLETS, rubber pellets uniform in shape and size and ideal for shock-absorbing playground base layers.

To be closer to the Southern European customers, Genan acquired the Portuguese Biosafe plant in Ovar in 2019. At the time of the acquisition, the plant had the capacity to recycle 25,000 tonnes of tyres per year, and after an upgrade of the production facilities, the newly acquired location was up to 40,000 tonnes per year by 2020, when the name change to Genan, S.A. also became a reality.

With the new forces and laboratory in Ovar, Genan developed colour-coated granulate in several sizes. The products were launched in 2021 under the names GENAN COATED INFILL and GENAN COATED TOP LAYER, respectively suitable as infill on artificial turf pitches and as top layer on playgrounds, running tracks, bicycle paths, etc.

30 YEARS OF RECYCLING EXPERIENCE

1990 VIBORG

Production started in Viborg, Denmark – production capacity: 35,000 tonnes/year

2003 ORANIENBURG

Production started at new plant in Oranienburg, Berlin, Germany – production capacity: 65,000 tonnes/year – authority approval, processing: 55,000 tonnes/year

2008 DORSTEN

Production started at new plant in Dorsten, NRW, Germany – production capacity: 70,000 tonnes/year – authority approval, processing: 65,000 tonnes/year

2010 KAMMLACH

Production started at new plant in Kammlach, Bayern, Germany – production capacity: 70,000 tonnes/year – authority approval, processing: 65,000 tonnes/year

2011 INCREASED CAPACITY

Production capacity in Viborg increased – new production capacity: 70,000 tonnes/year – authority approval, processing: 70,000 tonnes/year

2014 HOUSTON

Production started at new plant in Houston, Texas, USA – production capacity: 100,000 tonnes/year – authority approval, processing: 100,000 tonnes/year

2015 FINANCIAL RECONSTRUCTION

New management, financial reconstruction and reorganisation of Genan

2015 MICRONISED RUBBER POWDER

Production of micronised rubber powder started in Viborg

2017 RUBBER PELLETS

Production of GENAN PELLETS started in Viborg

2019 OVAR

Portuguese Biosafe plant acquired – production capacity: 25,000 tonnes/year

2020 GENAN, S.A.

Name change of Portuguese company to Genan, S.A. and upgrade of production plant in Ovar – new production capacity: 40,000 tonnes/year – authority approval, processing: 40,000 tonnes/year

2021 COLOUR-COATED GRANULATE

Production of GENAN COATED INFILL and GENAN COATED TOP LAYER started in Ovar

SUSTAINABILITY IS OUR CORE VALUE

You feel this when doing business with us

GENAN HOLDING A/S

Jegindøvej 16

DK-8800 Viborg

Tel.: +45 8728 3000

VAT no.: DK36557656

E-mail: info-dk@genan.com

– Striving for a sustainable future!